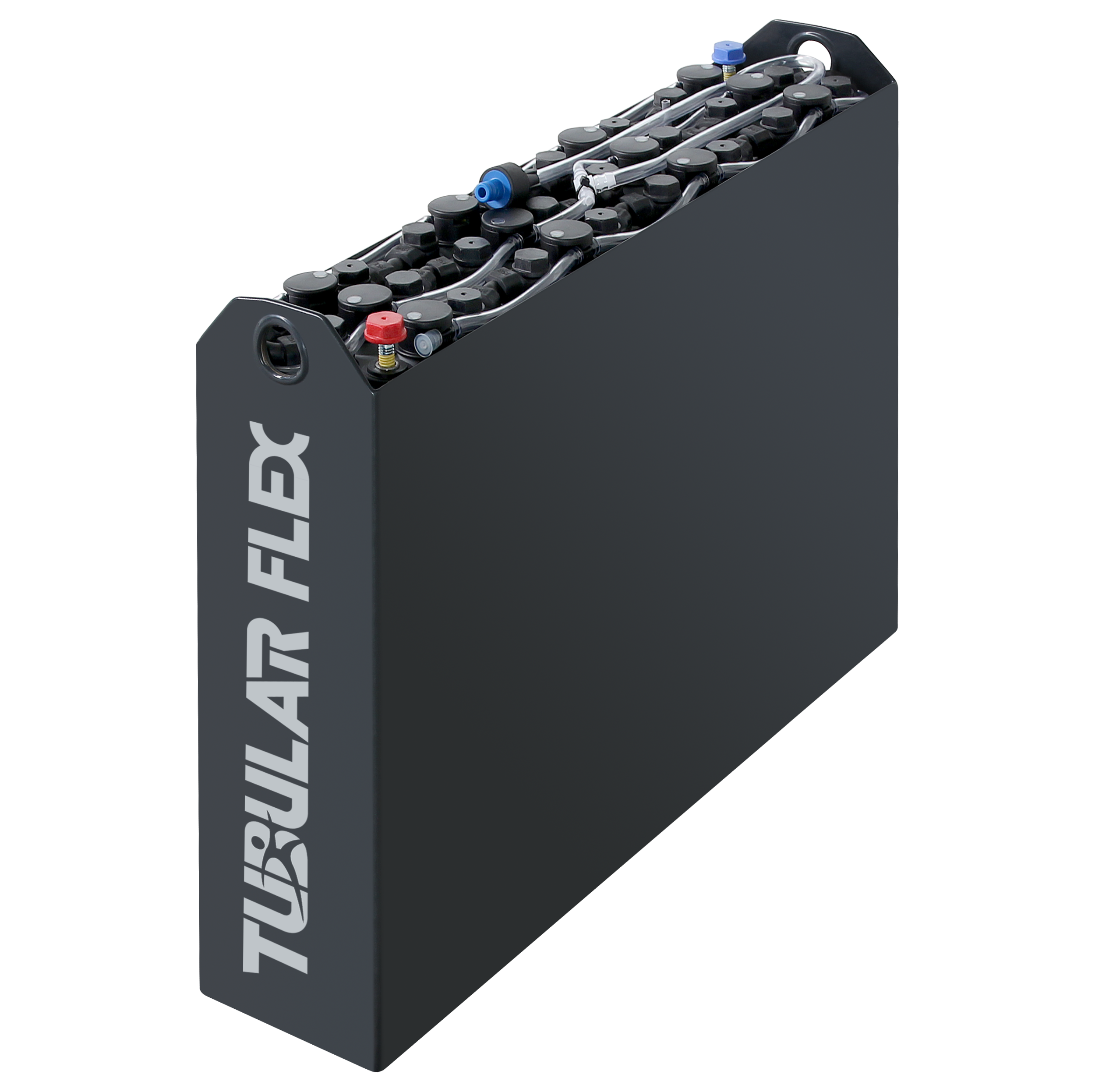

TRIATHLON TPzB

A solution with flooded lead-acid technology to minimize operating costs.

Low maintenance

Reliable electric battery operation.

Forklift batteries

Ensuring a secure energy supply.

Robust technology

With liquid electrolyte.

Our TRIATHLON TPzB batteries ensure safe and reliable power for electric lift trucks.

TRIATHLON TPzB

TRIATHLON TPzV-B batteries ensure safe and reliable power for forklift trucks. We are constantly and consistently working on new innovative power solutions for safe, cost-efficient, productivity enhancing and reliable motive power battery solutions.

Technical features

Width | 158 mm / 6.22 in |

British Standard (BS) cell | Yes |

Flex connectors and post bolts | Fully insulated |

Tubular technology | Yes |

Standardized rated capacities | From 64 to 1080 Ah |

Benefits

Replaceable bolt-on termination cables

Cell & battery comply with IEC 60254-2

Fully recyclable product, circular economy enabler